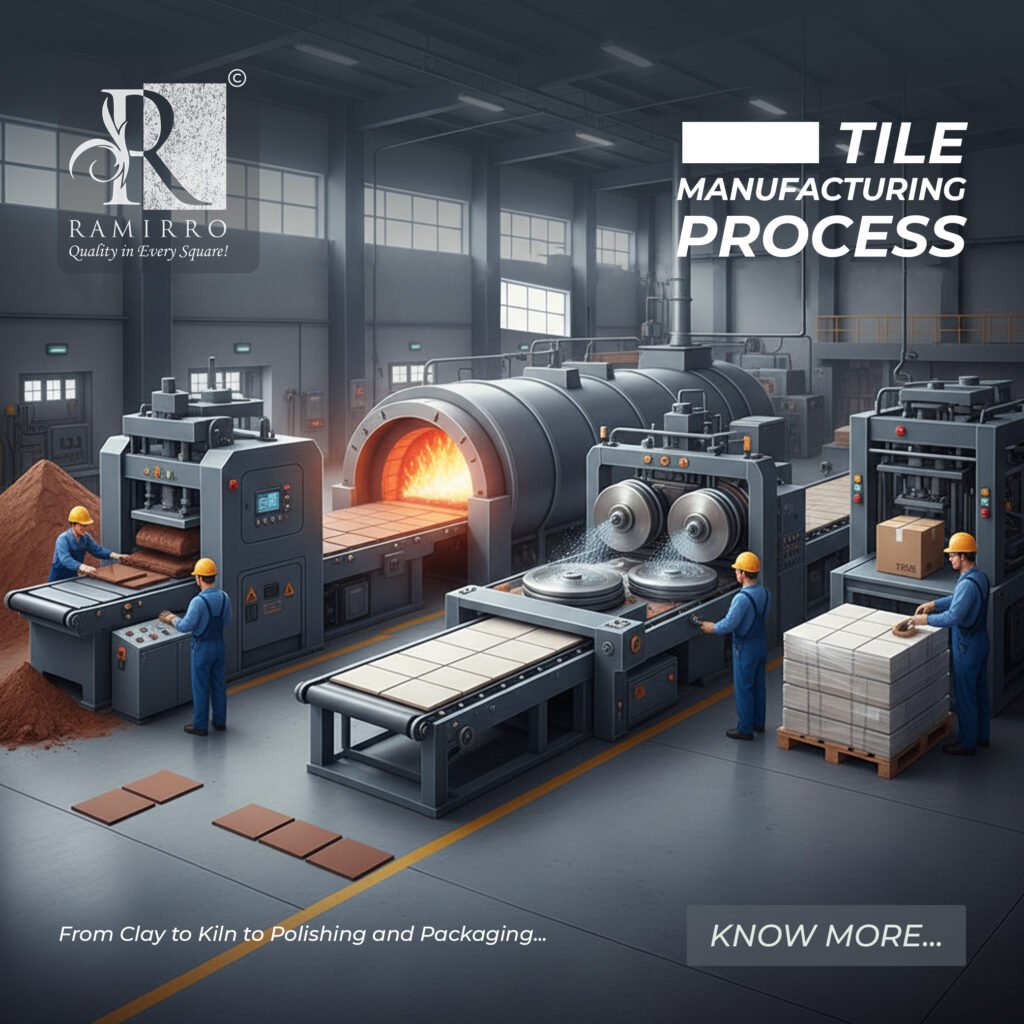

Every beautiful tile begins its journey deep in the earth from raw clay to a polished, durable surface that defines modern spaces. At Ramirro Ceramica, we combine the precision of Italian technology, the artistry of Spanish design, and the reliability of Indian manufacturing to create tiles that stand for quality and consistency. Our tile manufacturing process follows a meticulous path from clay preparation and kiln firing to polishing, calibration, and final packaging. Every stage is carefully monitored to ensure perfect thickness, shade accuracy, and long term durability. Whether it’s a single home or a large scale UAE project, Ramirro Ceramica delivers tiles engineered for strength, beauty, and lasting performance.

Every tile at Ramirro Ceramica begins as humble clay, shaped by expert hands and advanced machines, and ends its journey as a refined design element gracing high rise towers and homes around the world. Drawing on Italian technology, Spanish artistry in surface design, and the robust manufacturing strengths of India, Ramirro Ceramica is dedicated to ensuring unmatched precision and consistency in every tile. From sourcing premium raw materials to the final finishing touches, each stage is a testament to quality, beauty, and lasting performance delivering surfaces that inspire and endure in every setting.

Once the perfect clay blend is prepared, it enters the next vital stage grinding, mixing, and spray drying. At Ramirro Ceramica, the clay mixture is milled in large ball mills for up to 12 to 16 hours, ensuring every particle reaches a uniform size. This extended grinding process enhances the smoothness and strength of the final tile body.